ECOMAR Initiative:

Republic of Belarus

Purpose of ECOMAR's

Belarus Initiative.

ECOMAR’s expansion into Belarus represents a strategic move to blend profitability with impactful social and environmental objectives. As a landlocked country with a rich network of lakes and rivers, Belarus presents a unique opportunity for the development of a sustainable and technologically advanced aquaculture sector. Our Belarus initiative focuses on:

- Supplying Belarus and neighboring markets with high-quality, locally-produced fish products, catering to diverse economic segments.

- Offering technical support and introducing advanced aquaculture technologies to enhance the local industry and increase its competitiveness.

- Contributing to the preservation and restoration of native aquatic biodiversity, including valuable species like the sterlet.

- Boosting the economic development of rural areas through job creation and investment in modern infrastructure.

- Aligning with Belarus’s state programs for the development of the fishery industry and ensuring food security.

Technological Advancements and Benefits.

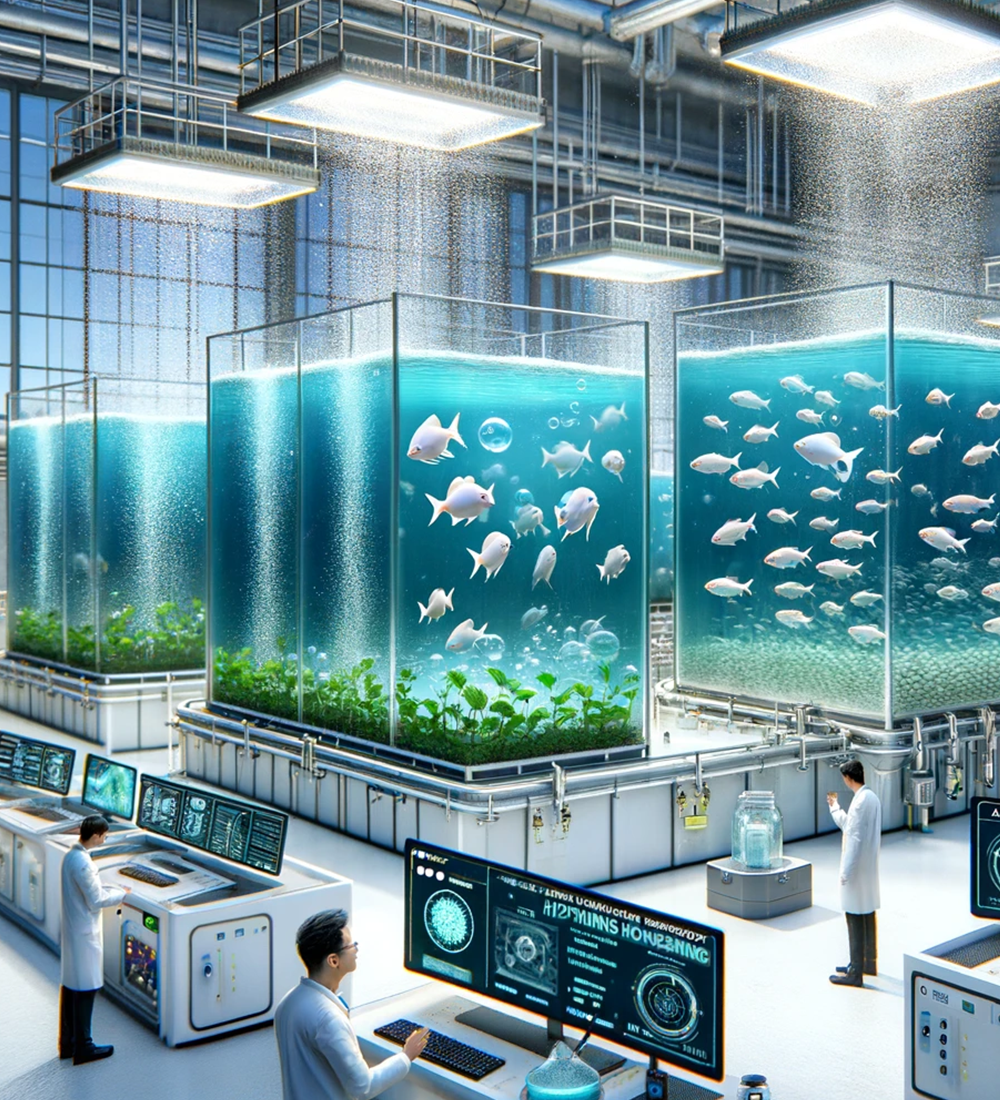

ECOMAR leverages cutting-edge technology to optimize aquaculture practices in Belarus, offering several key advantages:

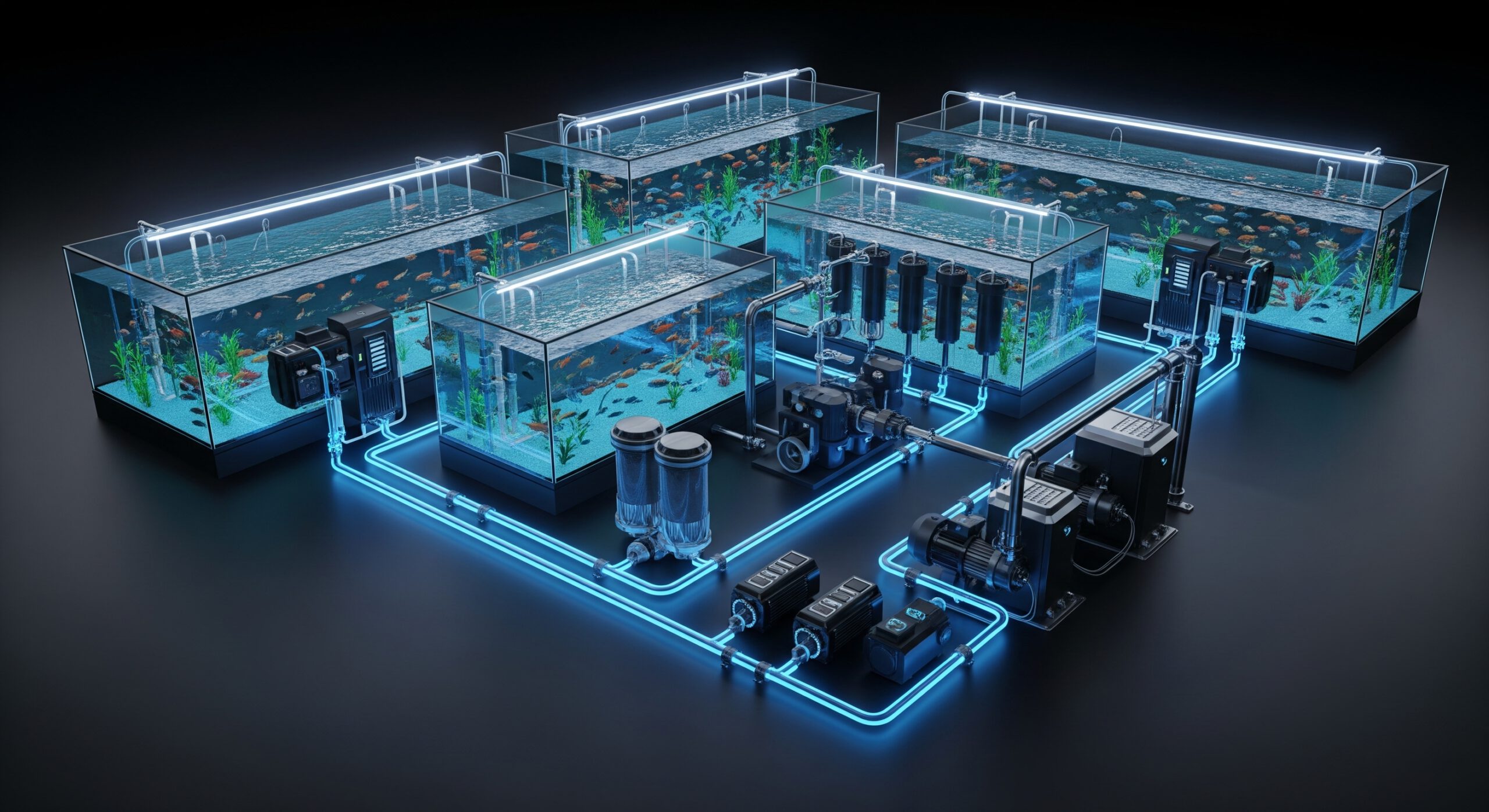

- Optimized Aquaculture Operations: ECOMAR’s unique modular design, featuring independent water cycles for each pool, enables precise control over water quality and hygiene. This design is crucial for preventing the spread of pathogens, ensuring healthier fish and safer products. It also allows for the customized management of different native and high-value fish species and their various growth stages, a critical factor for diversifying Belarus’s aquaculture output.

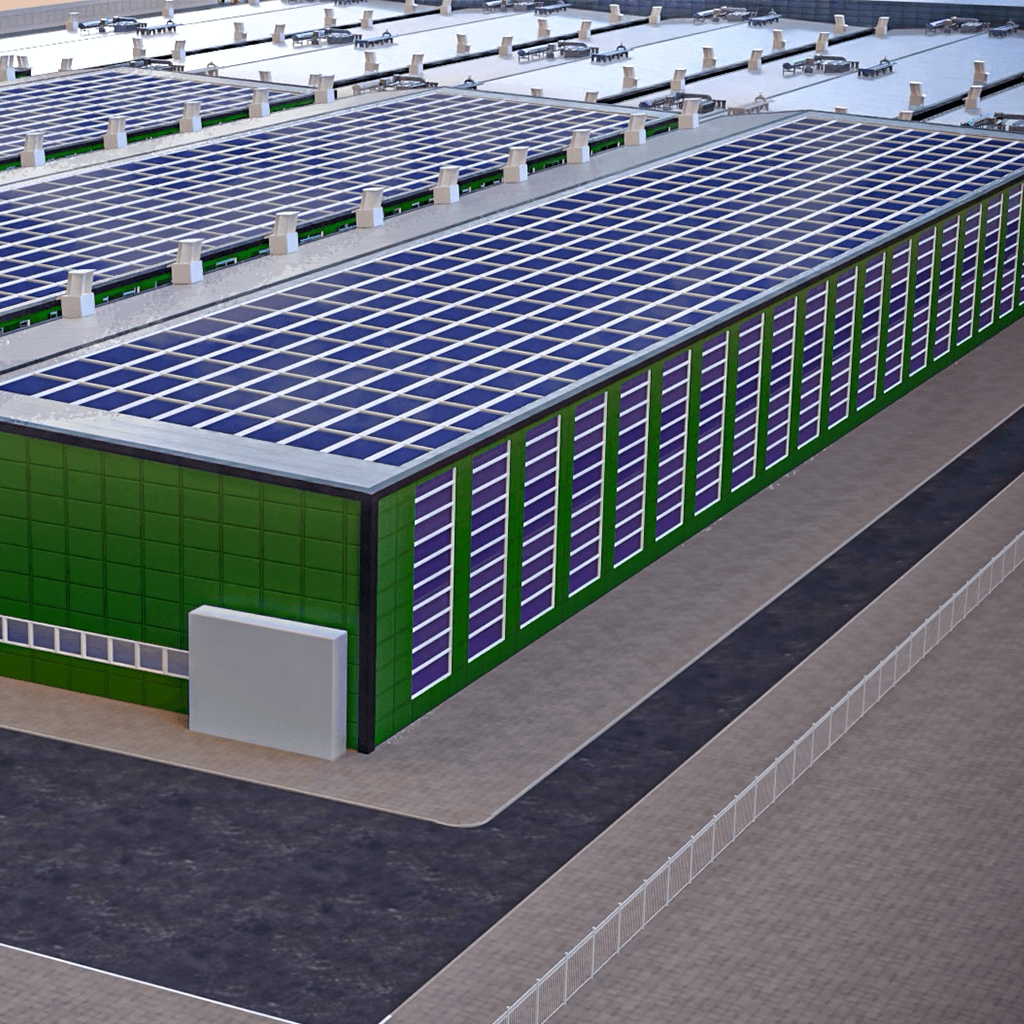

- Efficient and Eco-friendly Systems: The farm will utilize advanced technology, including energy-efficient heat pumps and cogeneration electric current generators, to maintain an optimal energy balance suitable for the Belarusian climate. This commitment to energy efficiency, coupled with continuous water quality monitoring within Recirculating Aquaculture Systems (RAS), exemplifies ECOMAR’s dedication to environmental responsibility and the minimal consumption of Belarus’s valuable freshwater resources.

- Innovation and Sustainability: Beyond being a fish farm, ECOMAR aims to be an innovation hub within the Belarusian aquaculture sector. Its scalable production, safe aeration methods, and reduced energy consumption will set new industry benchmarks, where sustainability and productivity are seamlessly integrated to support the nation’s food and economic goals.

Diverse Aquaculture Offerings

ECOMAR is set to become a pioneer in Belarusian aquaculture, cultivating an extensive array of fish species categorized by their market value and ecological importance. We will take pride in our sophisticated selection, ensuring a rich variety that caters to both domestic and export market demands.

Sturgeons

Beluga

Beluga

- Flavor: Delicate, buttery, and mild, prized for gourmet dishes.

- Nutritional Value: Rich in omega-3 fatty acids, protein, and essential minerals.

- Caviar: Soft texture, large eggs, and subtle nutty taste, considered the finest in the world.

- Usage: Often served raw as sashimi, in high-end recipes, or as smoked delicacy.

Kaluga

Kaluga

- Flavor: Rich, creamy, and slightly sweet, ideal for gourmet preparations.

- Nutritional Value: High in omega-3 fatty acids, proteins, and vitamins.

- Caviar: Firm texture, medium to large eggs, with a rich, buttery taste comparable to Beluga.

- Usage: Popular in fine dining, served as caviar or smoked, and pairs well with light sauces.

Siberian Sturgeon

Siberian Sturgeon

- Flavor: Mild, slightly earthy, with a firm texture, suitable for versatile culinary uses.

- Nutritional Value: Packed with omega-3 fatty acids, proteins, and essential nutrients.

- Caviar: Smaller eggs with a refined, nutty flavor, offering a more affordable gourmet option.

- Usage: Commonly used in smoked products, grilled dishes, or as caviar in mid-range fine dining.

Persian sturgeon

Persian sturgeon

- Flavor: Delicate and buttery, with a slightly nutty aftertaste, perfect for refined dishes.

- Nutritional Value: High in omega-3 fatty acids, proteins, and essential minerals.

- Caviar: Medium to large eggs with a creamy, rich flavor, often compared to Beluga caviar.

- Usage: Favored for premium caviar production and gourmet dishes, often served raw or lightly smoked.

Salmonids and Graylings

Masu

Masu

- Flavor: Mild and tender, with a slightly sweet taste, suitable for sushi and grilling.

- Nutritional Value: Rich in omega-3 fatty acids, vitamins D and B12, and high-quality protein.

- Usage: Popular for sashimi, smoked dishes, and light grilling.

Rainbow Trout

Rainbow Trout

- Flavor: Delicate and mild, with a slightly nutty and buttery texture.

- Nutritional Value: High in omega-3 fatty acids, proteins, and essential minerals.

- Usage: Versatile, used for baking, grilling, or smoking.

Brown Trout

Brown Trout

- Flavor: Rich, earthy flavor with firm, flaky texture.

- Nutritional Value: Good source of omega-3 fatty acids, vitamin D, and high-quality protein.

- Usage: Commonly grilled, pan-fried, or smoked.

Lake Salmon

Lake Salmon

- Flavor: Delicate, mild, and slightly sweet, similar to Atlantic salmon.

- Nutritional Value: High in omega-3s, proteins, and essential vitamins.

- Usage: Suitable for grilling, smoking, or use in gourmet recipes.

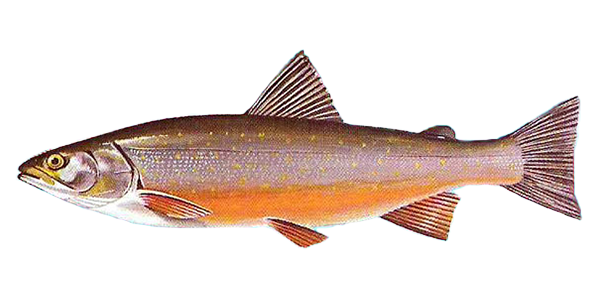

Arctic Char

Arctic Char

- Flavor: Mild and clean, with a rich buttery texture.

- Nutritional Value: Packed with omega-3 fatty acids, proteins, and antioxidants.

- Usage: Ideal for grilling, roasting, or sushi dishes.

Great Lake Char

Great Lake Char

- Flavor: Mild and delicate with a subtle, nutty finish.

- Nutritional Value: High in omega-3 fatty acids and vitamins A and D.

- Usage: Often smoked, grilled, or prepared as a delicacy in fine dining.

Siberian Taimen

Siberian Taimen

- Flavor: Rich and meaty, with a slightly gamey undertone.

- Nutritional Value: High in omega-3s, protein, and essential minerals.

- Usage: Best grilled, roasted, or used in hearty soups.

Grayling

Grayling

- Flavor: Delicate and slightly sweet, with a fine, flaky texture.

- Nutritional Value: High in omega-3 fatty acids and lean protein.

- Usage: Suitable for frying, baking, or smoking.

Siberian Lenok

Siberian Lenok

- Flavor: Mild and slightly sweet, with a firm texture.

- Nutritional Value: Rich in omega-3 fatty acids, protein, and trace minerals.

- Usage: Commonly used for grilling, baking, or in soups.

Whitefish Species

Nelma

Nelma

- Flavor: Rich and buttery, with a delicate, slightly sweet taste.

- Nutritional Value: High in omega-3 fatty acids, proteins, and vitamins.

- Usage: Ideal for smoking, frying, or as a delicacy in gourmet dishes.

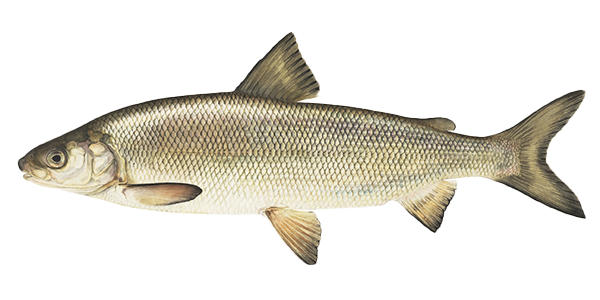

Common Whitefish

Common Whitefish

- Flavor: Mild, slightly nutty, with a fine, flaky texture.

- Nutritional Value: Packed with omega-3 fatty acids and lean protein.

- Usage: Versatile; great for smoking, grilling, or soups.

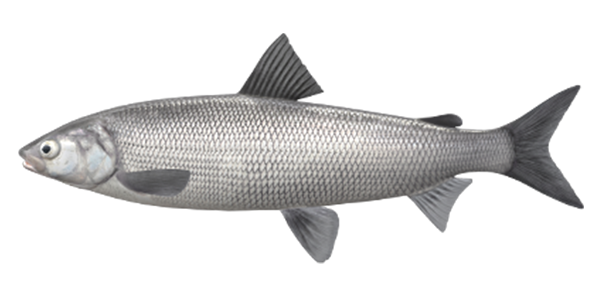

Muksun

Muksun

- Flavor: Rich and creamy, with a slightly sweet, nutty undertone.

- Nutritional Value: High in omega-3 fatty acids and essential nutrients.

- Usage: Commonly smoked, salted, or used in traditional dishes.

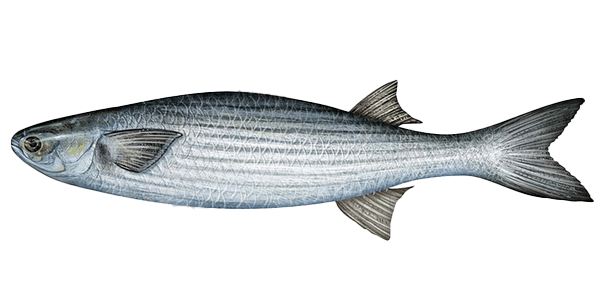

Baikal Omul

Baikal Omul

- Flavor: Delicate and slightly smoky, with a rich, buttery texture.

- Nutritional Value: Excellent source of omega-3 fatty acids and lean protein.

- Usage: Typically smoked, grilled, or used in local Siberian cuisine.

Perch-like Species

Barramundi

Barramundi

- Flavor: Mild, buttery, and slightly sweet, with a moist, flaky texture.

- Nutritional Value: High in omega-3 fatty acids, protein, and low in fat.

- Usage: Perfect for grilling, baking, or pan-frying; widely used in Asian and Australian cuisines.

Zander

Zander

- Flavor: Mild, delicate, and slightly sweet, with firm, white flesh.

- Nutritional Value: Low in fat, high in protein, and a good source of vitamins and minerals.

- Usage: Ideal for baking, frying, or steaming; commonly used in European cuisine.

COD FAMILY & Flatfish

Hamour

Hamour

- Flavor: Rich and mildly sweet, with a firm and flaky texture.

- Nutritional Value: A good source of lean protein, vitamins B6 and B12, and rich in omega-3 fatty acids.

- Usage: Ideal for grilling, steaming, or curry-based dishes; highly popular in Middle Eastern and Southeast Asian cuisines.

Olive Flounder

Olive Flounder

- Flavor: Mild, slightly sweet, and delicate, with a soft, flaky texture.

- Nutritional Value: Rich in protein, low in fat, and a good source of omega-3 fatty acids.

- Usage: Commonly used in sashimi, grilling, steaming, or frying; popular in East Asian cuisines.

Catfish & Eel Species

Clarias Catfish

Clarias Catfish

- Flavor: Mild and slightly sweet, with a firm, meaty texture.

- Nutritional Value: High in protein and low in fat, with essential vitamins and minerals.

- Usage: Commonly grilled, fried, or used in soups and stews; popular in African and Asian cuisines.

European Eel

European Eel

- Flavor: Rich, oily, and slightly sweet, with a tender, meaty texture.

- Nutritional Value: High in healthy fats, especially omega-3s, and a good source of vitamins A and E.

- Usage: Commonly smoked, grilled, or used in traditional dishes, especially in Japanese and European cuisines.

Mullet Species

Mullet

Mullet

- Flavor: Mild, slightly nutty, and firm, with a lean texture.

- Nutritional Value: High in protein, omega-3 fatty acids, and essential nutrients.

- Usage: Often grilled, baked, or smoked; popular in Mediterranean and Asian cuisines.

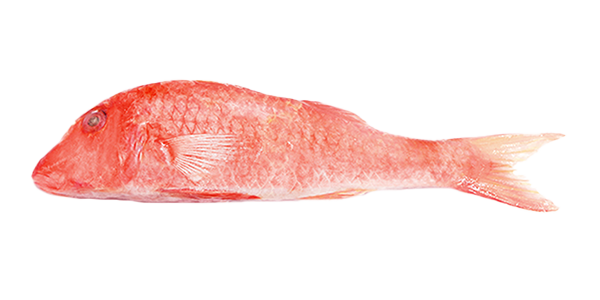

Red Mullet

Red Mullet

- Flavor: Delicate and slightly nutty, with a tender, flaky texture.

- Nutritional Value: High in protein, omega-3 fatty acids, and essential vitamins like B12 and D.

- Usage: Excellent for pan-frying, grilling, or incorporating into Mediterranean-style dishes; pairs well with citrus and herbs.

SCOMBRIDAE Species

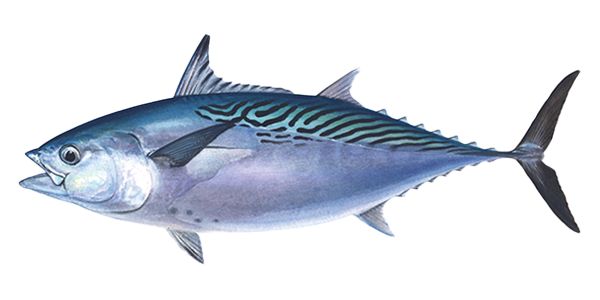

Mackerel Tuna

Mackerel Tuna

- Flavor: Bold, meaty, and slightly gamey, with a firm and oily texture.

- Nutritional Value: Rich in omega-3 fatty acids, high-quality protein, and essential vitamins like B12 and D.

- Usage: Best for grilling, smoking, or preparing raw as sashimi; widely used in Asian and coastal cuisines.

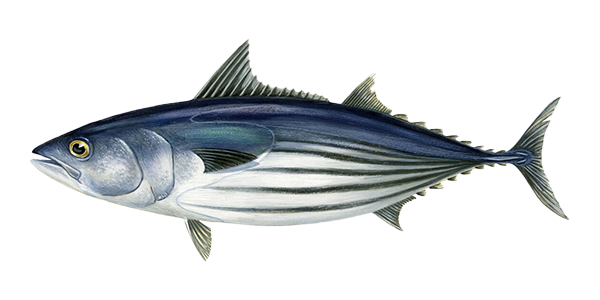

Skipjack Tuna

Skipjack Tuna

- Flavor: Strong and savory, with a rich, oily texture and a slightly sweet undertone.

- Nutritional Value: High in omega-3 fatty acids, lean protein, and essential vitamins such as B12 and niacin.

- Usage: Ideal for canning, grilling, or raw preparations like sushi and sashimi; a staple in global cuisines, especially in Japanese and Hawaiian dishes.

SERRANIDAE & CARANX CARANGUA

Red Grouper

Red Grouper

- Flavor: Mild and slightly sweet, with a firm, moist, and flaky texture.

- Nutritional Value: A great source of lean protein, low in fat, and rich in vitamins B6 and B12, as well as selenium.

- Usage: Perfect for grilling, baking, or steaming; popular in Mediterranean and Caribbean cuisines, often paired with citrus or spices.

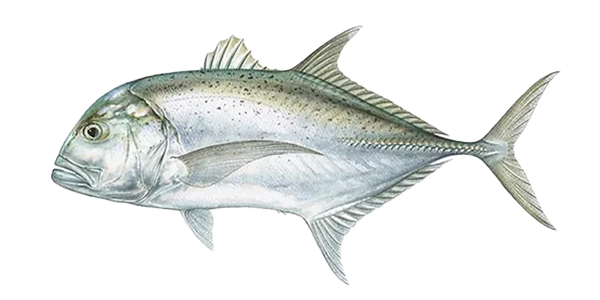

Caranx

Caranx

- Flavor: Robust and slightly tangy, with a firm and dense texture.

- Nutritional Value: High in protein and omega-3 fatty acids, with essential vitamins like B12 and minerals such as potassium.

- Usage: Excellent for grilling, frying, or stews; widely used in tropical and coastal cuisines, often served with bold spices or citrus-based sauces.

Crustaceans

Lobster

Lobster

- Flavor: Rich, sweet, and succulent with firm, tender meat.

- Nutritional Value: High in protein, low in fat, and a good source of zinc, selenium, and omega-3s.

- Usage: Often steamed, grilled, or baked; used in gourmet dishes like lobster bisque or thermidor.

Mud Crab

Mud Crab

- Flavor: Sweet and delicate with a soft, flaky texture.

- Nutritional Value: High in protein, low in calories, and a source of essential minerals.

- Usage: Popular in Asian cuisines, often steamed, curried, or stir-fried.

Tiger Shrimp

Tiger Shrimp

- Flavor: Mildly sweet with a firm, juicy texture.

- Nutritional Value: High in protein and low in fat, rich in selenium and vitamin B12.

- Usage: Suitable for grilling, frying, or steaming; widely used in seafood dishes worldwide.

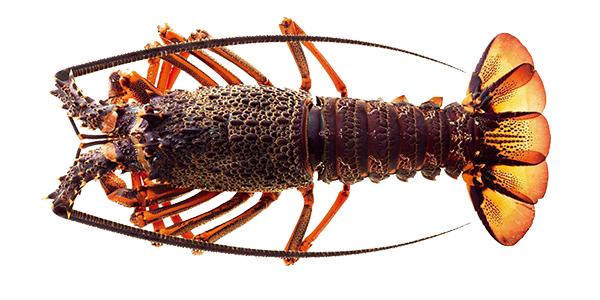

Spiny Lobster

Spiny Lobster

- Flavor: Sweet and tender, with a slightly firmer texture than regular lobster.

- Nutritional Value: High in protein, omega-3s, and essential minerals like phosphorus and magnesium.

- Usage: Often grilled or steamed; used in salads, soups, and gourmet seafood dishes.

Crustaceans

Belon

Belon Oyster

- Flavor: Bold and briny, with a metallic, nutty aftertaste.

- Nutritional Value: Rich in zinc, selenium, and omega-3 fatty acids.

- Usage: Typically served raw on the half-shell or lightly grilled.

Conwy

Conwy Oyster

- Flavor: Creamy and slightly sweet with a delicate brininess.

- Nutritional Value: High in protein, low in calories, and packed with minerals.

- Usage: Often enjoyed raw or with a light vinaigrette.

Ostrea Regal

Ostrea Regal

- Flavor: Rich, buttery, and slightly nutty with a hint of saltiness.

- Nutritional Value: Excellent source of zinc, iron, and omega-3 fatty acids.

- Usage: Perfect raw, grilled, or baked with herbs.

Kumamoto

Kumamoto Oyster

- Flavor: Sweet and creamy with a hint of melon or cucumber.

- Nutritional Value: High in protein and essential trace minerals.

- Usage: Often served raw as a delicacy with minimal garnish.

Pinctada Maxima

Pinctada Maxima

- Flavor: Rich and slightly sweet with a luxurious creamy texture.

- Nutritional Value: High in proteins, omega-3s, and minerals like zinc.

- Usage: Used for pearl production and gourmet dishes.

Tongyeong

Tongyeong Oyster

- Flavor: Mildly briny with a sweet, creamy finish.

- Nutritional Value: Packed with essential nutrients like zinc and selenium.

- Usage: Popular in Korean dishes, often grilled or served raw.

Spéciales de Claires

Spéciales de Claires Oyster

- Flavor: Balanced, slightly nutty, with a refined briny taste.

- Nutritional Value: High in omega-3s, zinc, and vitamin B12.

- Usage: Often served raw as a French delicacy.

Imperial

Imperial Oyster

- Flavor: Luxuriously rich and buttery, with a sweet finish.

- Nutritional Value: Rich in omega-3s, protein, and essential minerals.

- Usage: Highly sought after for raw gourmet preparations.

Osaka

Osaka Oyster

- Flavor: Bold and briny with a unique, slightly earthy undertone.

- Nutritional Value: High in lean protein and trace minerals.

- Usage: Often used in Japanese cuisine, raw or in soups.

Marennes-Oléron

Marennes-Oléron Oyster

- Flavor: Nutty and refined, with a smooth, briny finish.

- Nutritional Value: Excellent source of omega-3s and essential nutrients.

- Usage: Renowned in French cuisine, typically served raw or lightly steamed.

Extensive Range of Processed Fish Products.

Types of Fish Processing

At ECOMAR, our processing techniques will be diverse, ensuring that we cater to all culinary preferences and traditions in Belarus and beyond. Our processes will include:

- Pickling

- Salting

- Drying

- Canning

- Production of preserves

- Hot smoking

- Cold smoking

- Production of minced fish products (cutlets, sausages)

- Fish oil and fish meal manufacturing

Canned in Oil: Our canned fish in oil range will be a testament to our commitment to flavor and quality, featuring products like Smoked Trout in Oil and Smoked Sturgeon in Oil. These delicacies are perfect for both retail and gourmet markets.

Canned Natural: For those who prefer the unadulterated taste of fish, our canned natural selection will offer Natural Trout, Natural Carp, and Natural Zander. These products deliver the pure, clean flavors of the fish.

Products of Processing: Our processed fish products will be diverse, providing numerous options for both direct consumption and culinary use, including various fillet products, sausages, hams, and rolls.

Deep-Frozen Products: Recognizing the need for long-term storage without sacrificing quality, our deep-frozen products will ensure freshness and include steaks, fillets on the skin, and whole gutted fish.

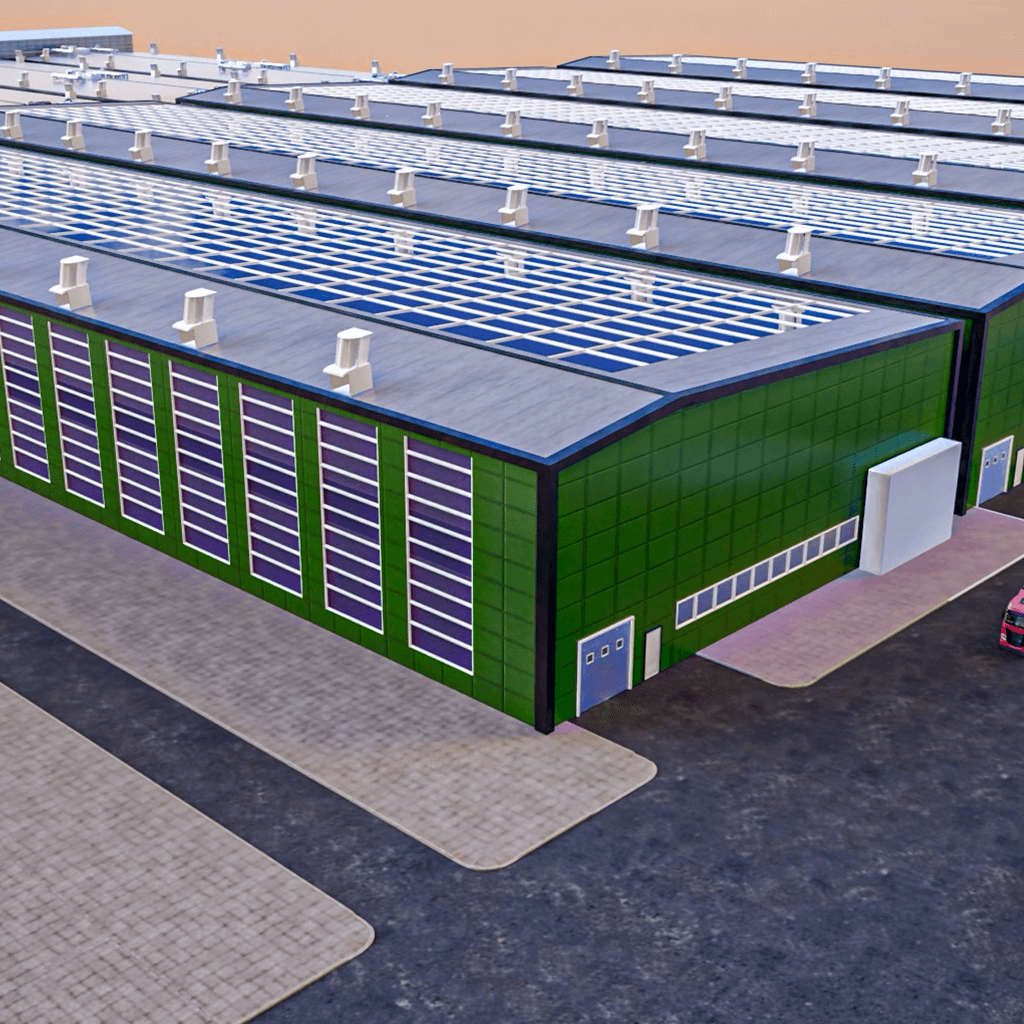

Strategic Location.

ECOMAR’s primary facility will be strategically located in the Vitebsk Region of Belarus, an area celebrated for its extensive network of lakes and rivers, often called the “Belarusian Lake District.” This provides an ideal environment for large-scale aquaculture.

- Infrastructure and Technology: ECOMAR’s facility will feature innovative insulated aqua modules, strategically positioned for optimal fish farming in the Belarusian climate. This setup enables precise environmental control, enhanced biosecurity, and increased production efficiency year-round.

- Our RAS (Recirculating Aquaculture System) will include:

- Multiple workshops with numerous pools.

- Spacious pools optimized for high-density farming.

- Sustainable Practices: Spanning a significant area, our sustainable approach will include advanced water management systems ensuring no harm to the surrounding pristine ecosystems. We will integrate hydroponics to recycle fish waste as nutrients for plants, creating a synergistic and circular economic model.

Advanced Controlled Closed Water Supply Technology.

Advanced Controlled Closed Water Supply Technology at ECOMAR will incorporate proven innovations integral to leading European enterprises. Key features include:

- Four Independent Fry Landings Annually: This approach allows for evenly distributed and boosted production, maximizing the capacity of our facilities.

- Modular Recirculating Water Supply Plant: This compact and efficient system enables rapid fish production in a small footprint, irrespective of external weather conditions, which is crucial for the Belarusian climate.

- Facility and Specialized Zones: ECOMAR’s facility will be divided into specialized zones for different stages of fish cultivation, including broodstock management, fish growth, and processing, all adhering to the highest environmental and security standards.

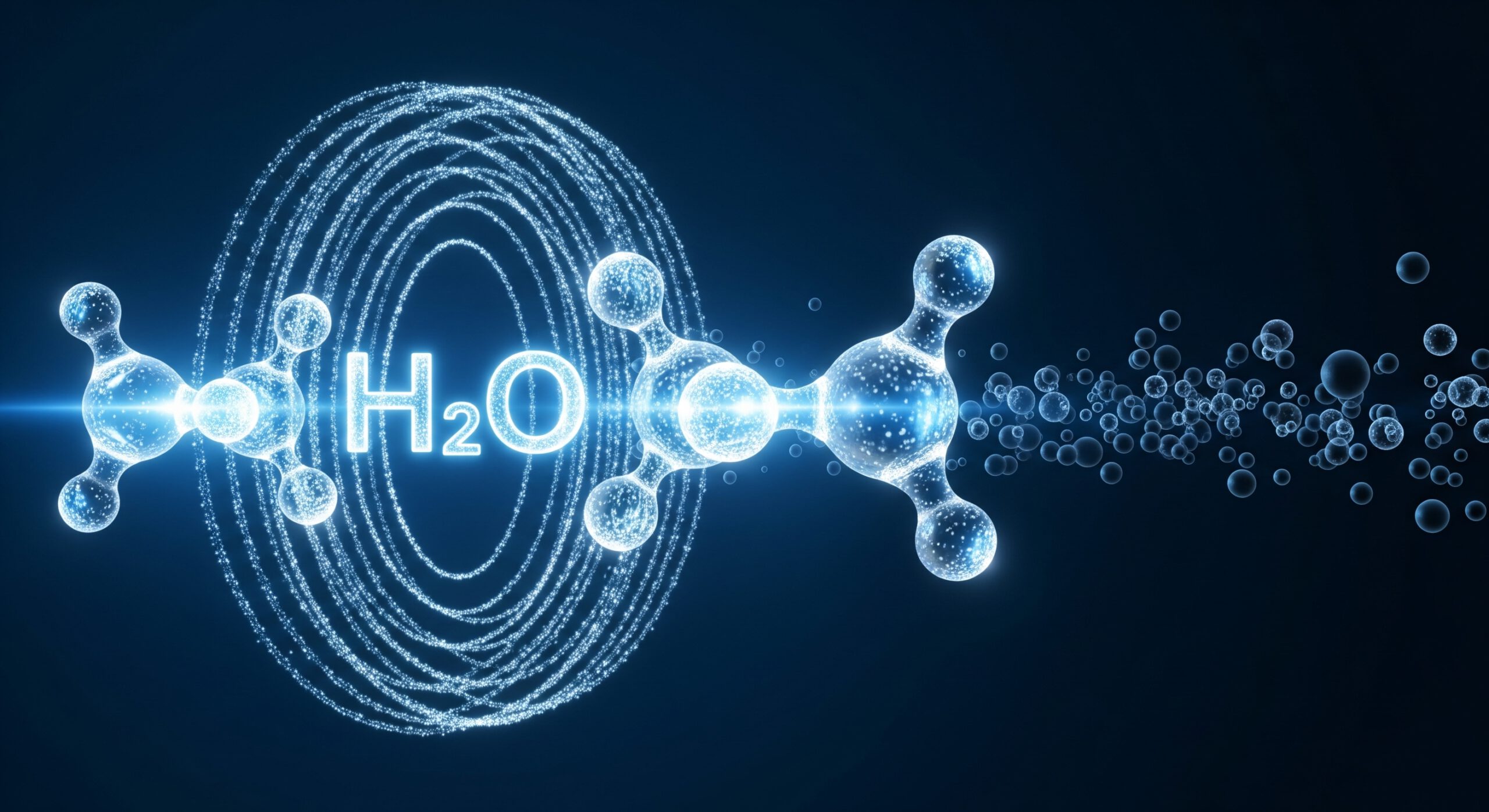

Wave Frequency Resonant Water Purification Technology.

While large-scale desalination is not required in Belarus, ECOMAR will utilize an advanced Wave Frequency Resonant Water Purification System. This innovative technology offers unparalleled economic, technical, and ecological advantages for treating and recycling water within our closed-loop systems.

- Key Features:

- Uses wave-frequency resonance to purify water, removing ammonia, nitrites, and other waste products with minimal energy input.

- Achieves high efficiency in water recycling, drastically reducing the need for fresh water intake.

- Operates without harmful chemicals, ensuring a clean, sustainable process that protects Belarus’s natural water bodies.

Advantages of RAS Technology.

ECOMAR’s adoption of Recirculating Aquaculture Systems (RAS) in Belarus offers numerous benefits:

- Enhanced Fish Growth: RAS technology creates optimal, stable conditions, accelerating fish growth rates for quicker market readiness.

- High-Density Aquaculture: Controlled environments enable high-density fish farming (e.g., up to 70 kg/m² for sturgeon), maximizing production in a limited space.

- Production Control & Environmental Stability: Ensures consistent quality and yield, independent of Belarus’s seasonal weather changes.

- Resource Efficiency: Saves water, land, and energy, demonstrating ECOMAR’s commitment to sustainability.

Eco-Friendly: Guarantees ecologically clean production and final products, meeting the highest European environmental standards.

Integrating Aquaponics, Aeroponics, and Fish Farming.

ECOMAR integrates aquaponics and hydroponics with fish farming to create a sustainable cycle where fish waste provides essential nutrients for plant growth, and the plants in turn purify the water for the fish.

This will allow for the co-production of fresh vegetables, herbs, and berries alongside our fish, creating additional revenue streams and promoting a circular economy.

HYDROGEN ENERGY TECHNOLOGY.

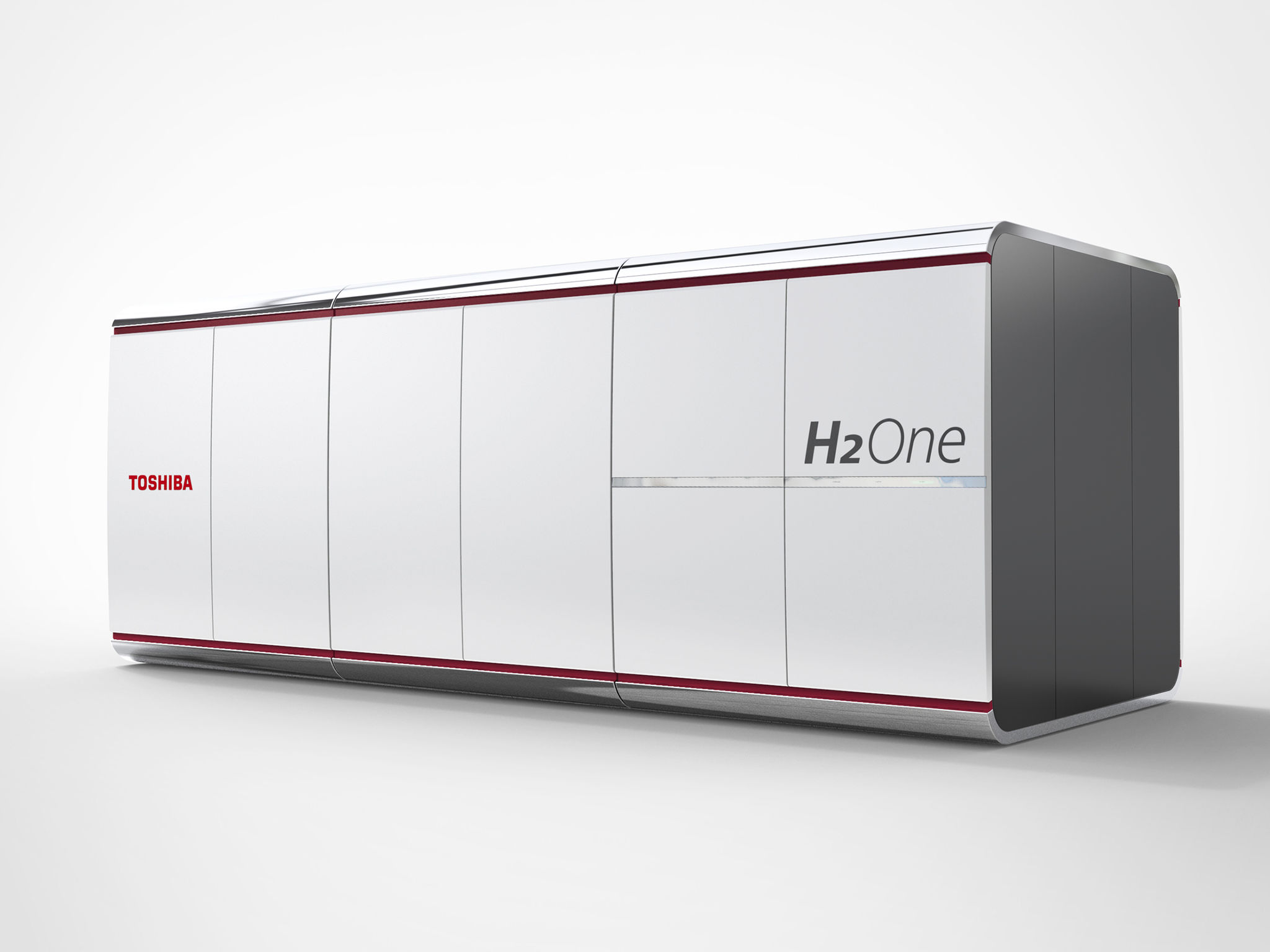

Toshiba H2One™: Pioneering Sustainable Hydrogen Solutions for Energy Demands

Toshiba Energy Systems & Solutions Corporation (Toshiba ESS) has introduced the H2One™, an autonomous hydrogen energy supply system, to support SP Group’s research efforts in Singapore. Designed to address the challenges of limited land and growing energy demands, H2One™ integrates renewable energy sources to electrolyze water, producing hydrogen for CO2-free electricity and hot water generation.

Compact and versatile, the 20-ft container system features metal hydride storage, making it ideal for Singapore’s constrained spaces. H2One™ has been operational in Japan since 2015, aiding electricity operators in managing demand fluctuations and optimizing energy management operations.

SP Group, Singapore’s national power grid operator, is conducting feasibility studies on H2One™ under local grid conditions, exploring green hydrogen as a viable energy solution. These studies aim to support Singapore’s goals for sustainable energy integration.

Toshiba ESS, with expertise in hydrogen technologies, envisions expanding its H2One™ solutions globally, fostering the adoption of clean hydrogen to transform energy networks.

Innovative Fish Farming and Processing Technologies.

At the forefront of fish cultivation and processing, we employ the groundbreaking, patented hydrogen technologies developed by Prof. Khachatryan, unrivaled anywhere in the world. These technologies include:

Advanced Water Treatment and Activation: This specialized technique significantly accelerates the growth of fry by 1.5 to 2 times and increases their survival rate to nearly 100% (compared to the standard 60-70% survival rate). This process ensures a more efficient and successful fish breeding program.

Patented Fish Feed Additive: Our unique, patented feed additive, when mixed with water, releases a high concentration of hydride ions. This innovation enhances the fish’s body mass even with low protein and fat content in their feed, boosts egg production, strengthens their immune system, and consequently, reduces the risk of chronic diseases and increases survival rates during various illnesses.

Electrochemically Activated Mineral Solution for Fish Meat Processing: The fish meat is processed in a special, patented, and world-unique electrochemically activated mineral solution. This method ensures complete disinfection of the fish meat, extends its shelf life during preservation without the need for additional chemical preservatives, thus rendering the product ecologically pure.

Revolutionary Caviar Processing: During caviar processing, it is disinfected in the same mineral solution and seasoned with a unique ‘hydrogen salt’, unparalleled in the world. This innovative approach enhances the caviar’s beneficial properties manifold, imbuing it with antioxidant properties, enriching its flavor profile, extending its shelf life without chemical preservatives, and preserving its original freshness and taste.

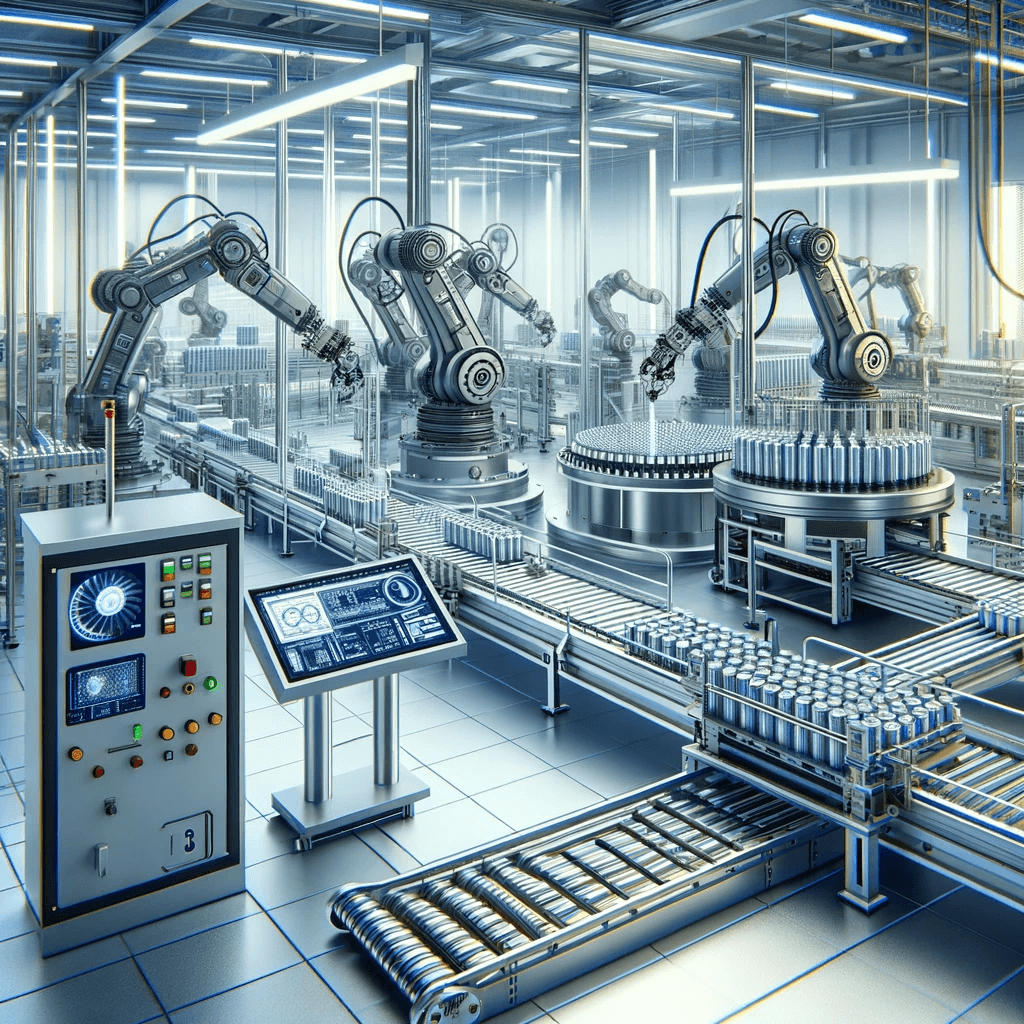

Advanced Can Production.

ECOMAR is proud to introduce its proprietary can production, employing sophisticated Japanese equipment. Using the advanced Alfons Haar machinery, we produce the thinnest 2-piece fish DRD can in the market, with a 0.14 DR8 thickness. This innovation results in a 20% reduction in metal usage, saving over $1,000,000 annually per production line.

Our patented sidewall bead design, coupled with a tab-safe bottom, prevents accidental openings and enhances can stability, especially for easy-open ends. This design exemplifies our commitment to quality and safety.

ECOMAR’s cans are further distinguished by Royal Can Industries’ automatic 6-color printing technology, recognized globally for its high-quality finish.

We offer comprehensive services, including metal coating and printing, and provide expert consultation in packaging product design. ECOMAR remains a leader in can production through continuous innovation and dedication to excellence.

Drones in Security Service.

Forget the outdated security technologies of the past. The era of unreliable alarms and inattentive human guards is over. Today, a modern security officer is not a person, but a flying robot – a drone. Drones have revolutionized aerial security, elevating the concept of surveillance and safety to unprecedented heights. These unmanned aerial vehicles (UAVs) are now pivotal in safeguarding properties, territories, and people, and play a crucial role in identifying and curtailing illegal activities.

What sets drones apart? Their tireless and unwavering efficiency. Unlike human guards, drones are not prone to distractions or fatigue. They don’t take breaks or fall asleep on the job. A patrol drone operates continuously, maintaining peak effectiveness around the clock.

Introducing The Bee and The Hive:

- The Bee: A lightweight drone designed for optimal safety and performance. It features autonomous flight, high-quality video capabilities, and precise landing and charging.

- The Hive: The central hub for The Bee. It not only houses and charges the drone but also processes and analyzes sensor data with cutting-edge AI technology.

PROGRAM FOR THE PERIOD 2025 – 2030.

- Phase 1 (2025-2026): Complete the construction of the main aquaculture facility in the Vitebsk region and begin initial production cycles. Establish a domestic distribution network to supply major retail chains in Minsk, Vitebsk, and other regional centers.

- Phase 2 (2027-2028): Scale up production to full capacity. Launch a line of branded, value-added products (smoked, canned, ready-to-eat) for the Belarusian market. Begin exporting high-value products like sturgeon and caviar to the Eurasian Economic Union (EAEU) and explore opportunities in the European Union.

- Phase 3 (2029-2030): Establish a network of branded retail outlets and potentially Food Trucks in major Belarusian cities to enhance brand visibility and direct customer access. Invest in research and development to domesticate and farm new, valuable local fish species, further contributing to Belarus’s food security and export potential.